van Dijke Destoner SN-series

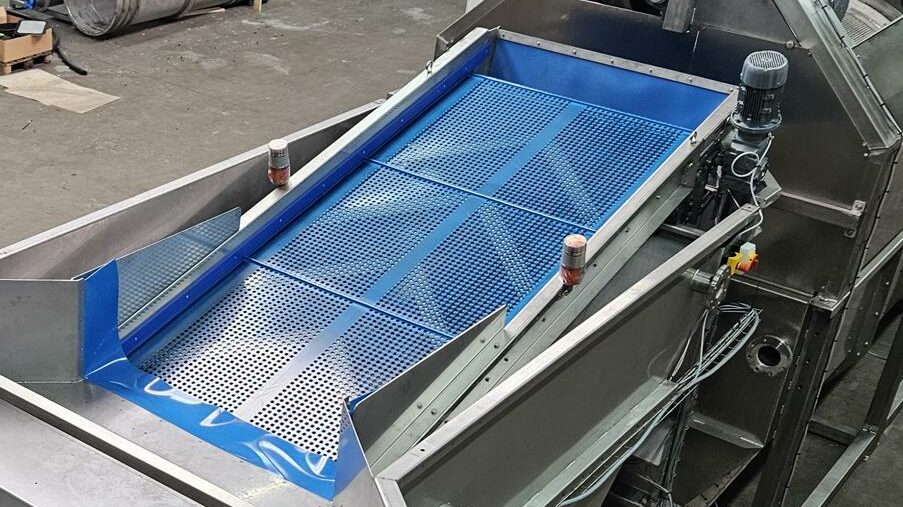

Built for the toughest conditions, the Van Dijke SN-Series Destoner delivers uncompromising performance in removing stones, clods, and other heavy contaminants from produce such as potatoes and carrots. Its advanced, adjustable water circulation and integrated sand and clay filtration ensure pinpoint separation accuracy with minimal water consumption.

Innovative and sustainable

The Destoner SN-series delivers highly efficient removal of heavy contaminants such as stones and clods through a precisely adjustable upward water flow, ensuring optimal separation performance for a wide range of produce. Its smart internal water circulation system minimizes water consumption, requiring only a small amount of fresh or recycled water. An advanced sand and clay filtration system maintains consistently clean process water, maximizing uptime and performance. Built to demanding industrial standards and fitted with premium brand components, the Destoner SN-series features a heavy-duty discharge belt for reliable, long-term operation.

Industrial destoning with minimal water usage

Combi vs single unit

Van Dijke also manufactures integrated combi-machines that combine a destoner and a drum washer in a single unit. However, a processing line with a separate destoner followed by a separate drum washer offers clear and decisive advantages.

With two standalone machines, water level and water flow can be adjusted independently for each process step, allowing both the destoning and washing stages to be optimized to perfection. In contrast, combi-machines offer limited adjustment flexibility, which directly impacts washing intensity and overall performance.

Separate machines also deliver a noticeably cleaner end product. The destoner operates with relatively dirty water and effectively functions as a pre-washer, removing sand, stones, and clods at an early stage. As a result, the drum washer can operate with significantly cleaner water and reduced water consumption, achieving superior washing quality and higher overall capacity.

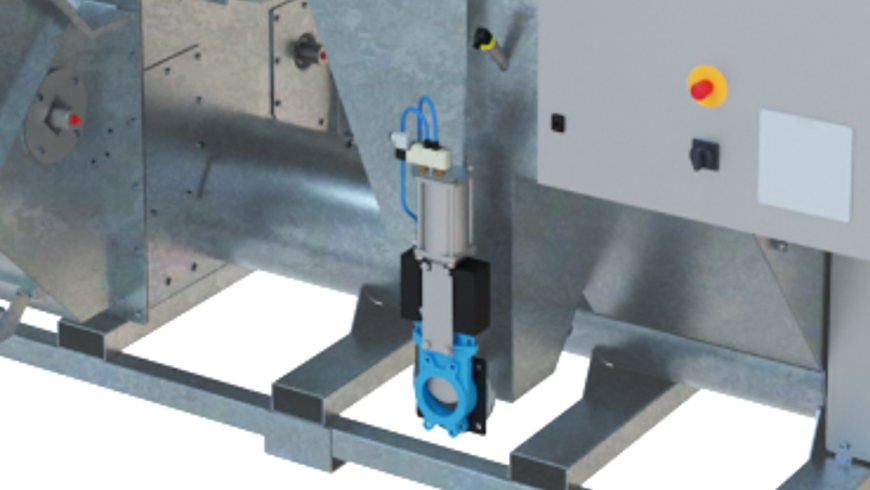

Integrated hedgehog belt

The unit can be seamlessly expanded with a hedgehog unit / leaf separator, mounted directly on top of the infeed hopper—eliminating the need for additional floor space. This smart add-on efficiently removes the majority of organic material, such as leaf debris, from the produce before further processing. The result is a cleaner produce flow, improved downstream performance, and maximum use of available space. Click the link below for more information about the leaf separator.

Compact SK-series destoner

The SN-series destoners are engineered for high-capacity operations, with throughput starting at 25 tons per hour. For lower-capacity applications, Van Dijke offers the compact and efficient SK-series destoners, delivering the same reliable performance in a smaller footprint. Click this link to discover more about the SK-series destoners and find the solution that best fits your processing needs.

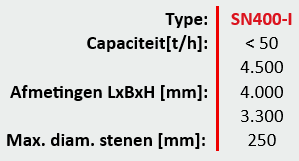

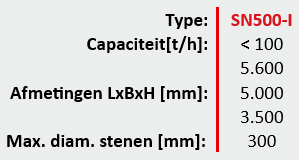

Capacities and models

Explore our standard capacities and configurations below. Need more? We design tailor-made solutions to maximize your performance and ROI. Available in galvanized/stainless steel combinations or fully stainless steel for ultimate durability and food-safety requirements.

Destoner SN400-I

Capacity up to 50 t/h

Destoner SN500-I

Capacity up to 100 t/h

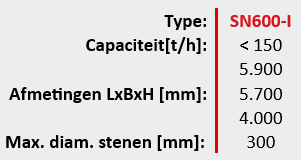

Destoner SN600-I

Capacity up to 150 t/h