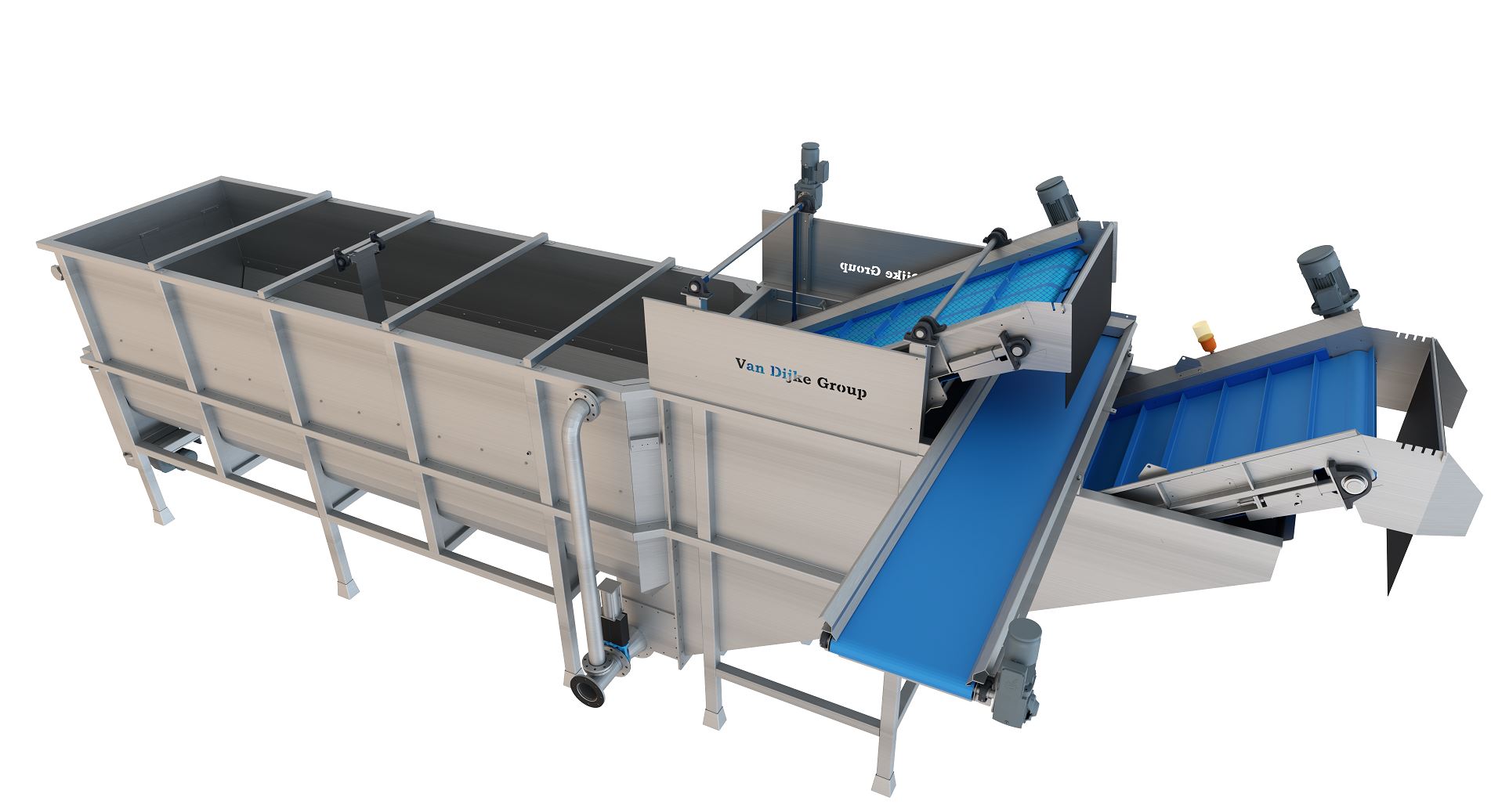

van Dijke Presoak unit

The Van Dijke Presoak Unit is designed for efficient pre-soaking, pre-washing, and optional pre-heating of potatoes and other root crops. Ideal for products heavily coated with clay, soil, or sand, this unit ensures a thorough initial clean, making it an essential starting point for any high-quality washing and processing line.

Effective pre-soaking through complete immersion

In the Presoak Unit, the product is completely immersed in water. The combination of immersion and gentle friction between the product effectively loosens clay and sand.

This results in an excellent pre-soaking and pre-washing result, even before the product enters the next processing steps.

The Van Dijke Pre-soaking Unit can be used for multiple purposes:

- Pre-soaking and pre-washing of heavily soiled products

- Preheating the product with warm water

- Removing foliage, roots and other floating parts

By gradually heating the product, it is better protected against impact and fall damage further down the line. This makes the unit particularly suitable for applications in the fresh market, such as table potatoes.

Great attention has been paid to product protection and reliability in the design.

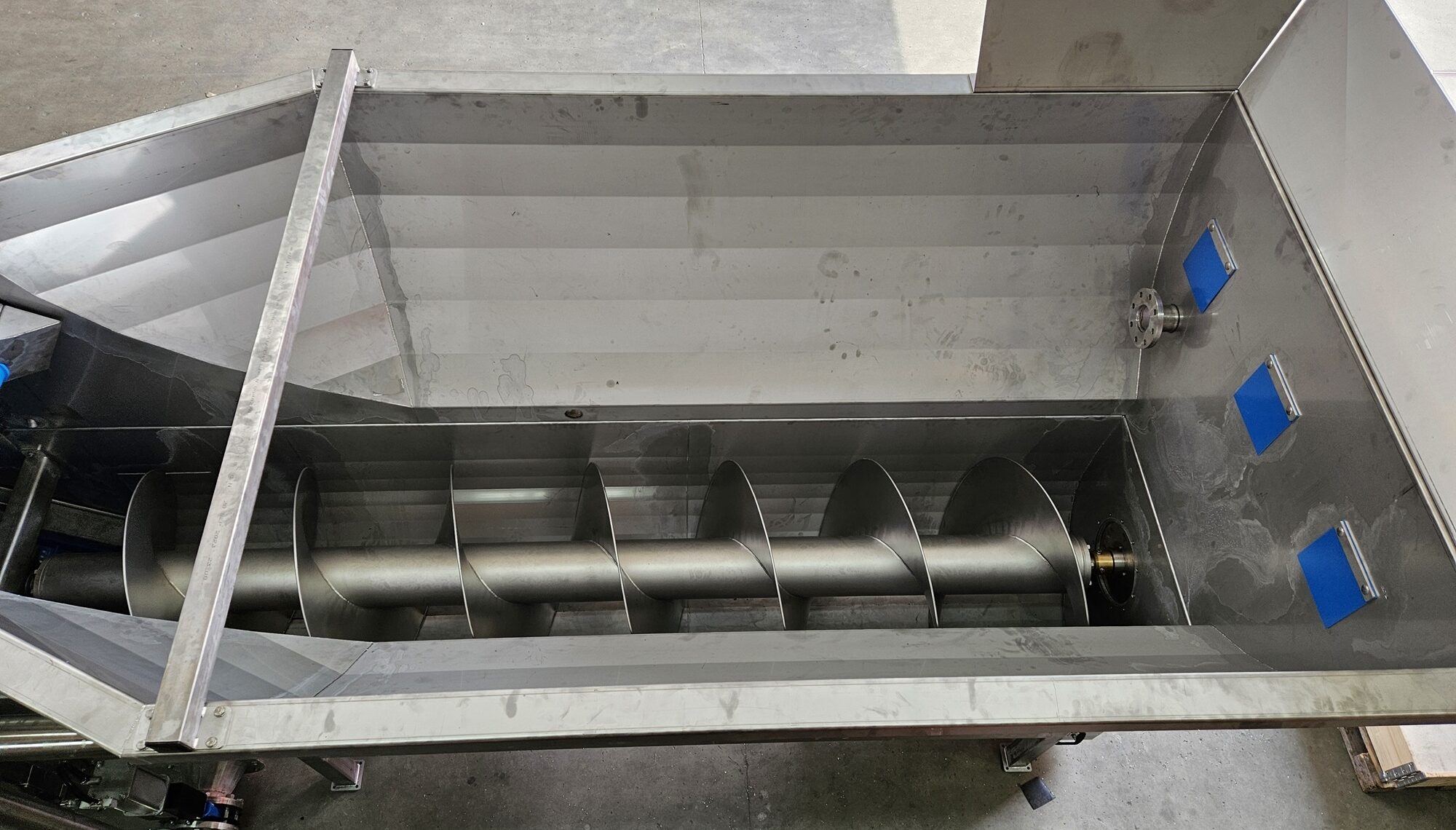

Smart separation of dirt and slugde

The Presoak Unit is equipped with an efficient sludge removal system that continuously removes sand and clay via a shaftless auger. The separated sludge can be discharged directly to a water recycling system or settling basin.

Optionally, the unit can be equipped with a wet leaf separator, which removes foliage and other floating contaminants (such as glass potatoes) from the product.

The Presoak Unit characterized by:

-

Gentle, product-friendly treatment;

-

Industrial building quality;

-

Constant and controlled product throughput;

-

Adjustable retention time thanks to frequency drives on the augers.

The product is transported evenly through the water-filled unit by means of augers. The length of time the product remains in the unit can be precisely adjusted, allowing the pre-soaking process to be optimally tailored to the product and degree of contamination. During this process, dirt and sludge are actively separated, while the product is transported in a controlled manner to the next step in the processing line.

Capacities and models

Explore our standard capacities and configurations below. Need more? We design tailor-made solutions to maximize your performance and ROI. Available in galvanized/stainless steel combinations or fully stainless steel for ultimate durability and food-safety requirements.

PSU 1000-1

Capacity up to 20 t/h

PSU 1200-1

Capacity up to 40 t/h